MTF-1 High Quality 33cm DTF PET Film-Single Side

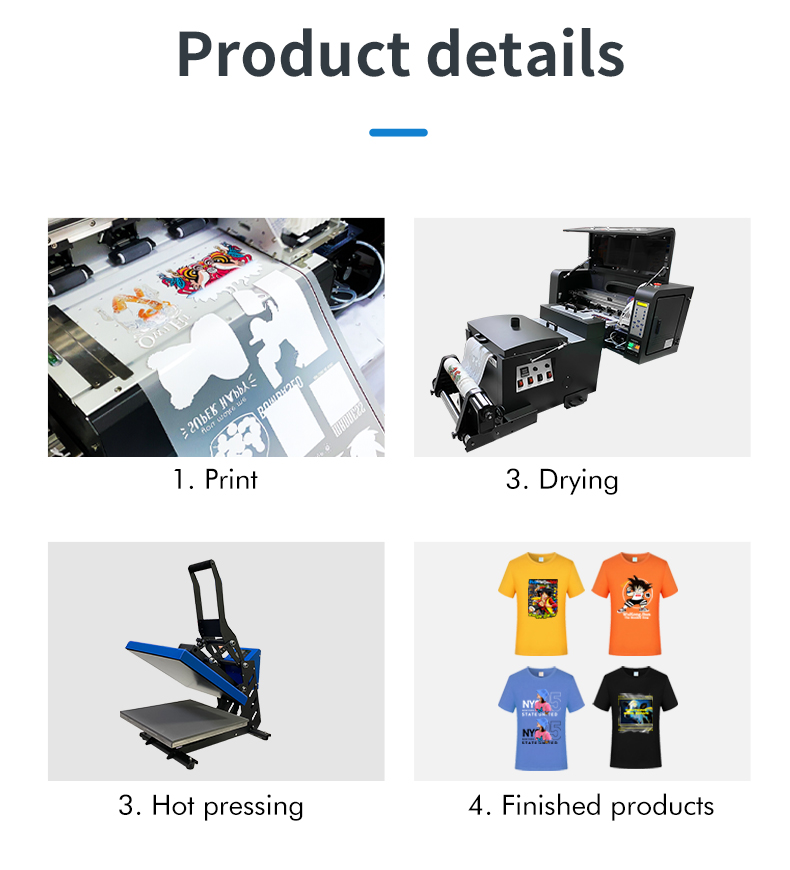

This new printing solution could also take place of traditional screen printing,imagines is outputted directly and controlled by printing software.and it has more flexible application than DTG,it is not only suitable for cotton,but also for polyester and other type fabric(.Eco-friendly processing and easily operation makes this solution applied in different industries,factory,shop and personal store etc.

Transparency:Transparent

Usage:DTF Printing

Material:PET

Size:30cm*100M

Thickness:75mic

Apply to Printing:offeset printing

Peeling Method:hot & cold peel

Usage:DTF Printing

Material:PET

Size:30cm*100M

Thickness:75mic

Apply to Printing:offeset printing

Peeling Method:hot & cold peel

Description

High Quality DTF PET Film

glossy and hot peel release film,the heat transfer temperature between 130-150 ℃, the heat transfer effect completely, and no residual color.Is the commonly used heat transfer film substrate on the heat transfer market at present. Because of the back coating the adhering layer, Can prevent the adhesion failure of products from long distance transportation and pressure.And isolation of paper and transportation costs can be saved. Through multi-channel applicator precision processing and become,quickly absorb ink layer, high surface smoothness, no matter fine patterns or colors printing can achieve the ideal effect.

Features:

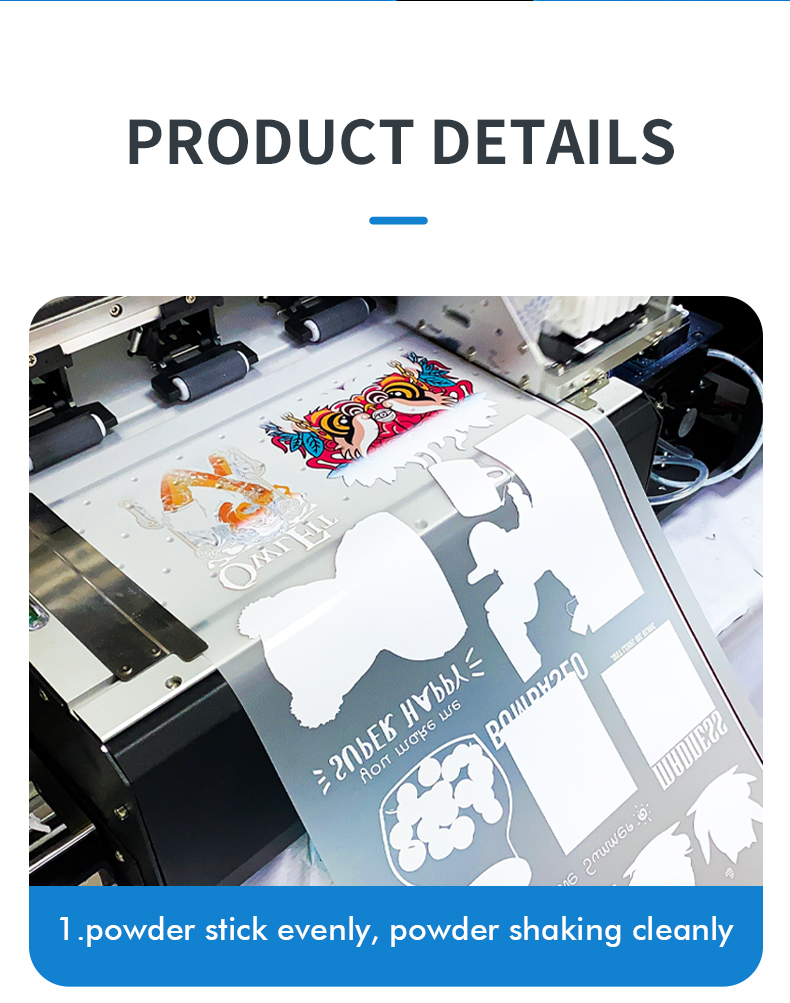

1.No cutting,simple and convenient

2.Easy operation

3.No waste

4.Low cost can print high quality results.

5.Soft hand feeling,excellent breathability

6.Bright and vivid color

7.Good for fastness

8.Good stretch resistance and resilience

9.Cotton,polyester and other fabric are all available to be transferred

1.No cutting,simple and convenient

2.Easy operation

3.No waste

4.Low cost can print high quality results.

5.Soft hand feeling,excellent breathability

6.Bright and vivid color

7.Good for fastness

8.Good stretch resistance and resilience

9.Cotton,polyester and other fabric are all available to be transferred

FAQ

1. What is machine warranty ?

1 year warranty for non-man-made damage, except for consumables and consumable parts ( Print-head )

2. How many times can be washed ?

Its printing durability is fanstatic, it have been tested to wash over 50 times, and printing is still great!

3. How many sheets film can print with 1 set inks ?

EP L1805 : about 900 sheets for white, and 1400 sheets for colored ink

EP L1800 : About 700 sheets for white, and 1100 sheets for colored ink

( All information for reference only )

4. How many sheets film can be used for 500g powder ?

For A4 size: about 3500 sheets

For A3 size: about 2700 sheets

( All information for reference only )

5. How long can we keep the inks/ powder/ PET film ?

Once the package is opened, it is recommended to use it within 6 months to avoid poor transfer effect due to moisture and other reasons.

6. Why the poor color printout happened ?

1. White inks got precipitated after few hours no printing. --- pls shake the ink tank gently before printing.

2. Print-head blocked --- Process Head-Cleaning on computer

7. Cold peeling or hot peeling ?

Both are available. For hot peeling, pls press the tshirt 5 seconds more, you will get great durability printed effect.

8. Which model printer is suitable for this solution ?

Recommended EP L1805, EPL1800.

1 year warranty for non-man-made damage, except for consumables and consumable parts ( Print-head )

2. How many times can be washed ?

Its printing durability is fanstatic, it have been tested to wash over 50 times, and printing is still great!

3. How many sheets film can print with 1 set inks ?

EP L1805 : about 900 sheets for white, and 1400 sheets for colored ink

EP L1800 : About 700 sheets for white, and 1100 sheets for colored ink

( All information for reference only )

4. How many sheets film can be used for 500g powder ?

For A4 size: about 3500 sheets

For A3 size: about 2700 sheets

( All information for reference only )

5. How long can we keep the inks/ powder/ PET film ?

Once the package is opened, it is recommended to use it within 6 months to avoid poor transfer effect due to moisture and other reasons.

6. Why the poor color printout happened ?

1. White inks got precipitated after few hours no printing. --- pls shake the ink tank gently before printing.

2. Print-head blocked --- Process Head-Cleaning on computer

7. Cold peeling or hot peeling ?

Both are available. For hot peeling, pls press the tshirt 5 seconds more, you will get great durability printed effect.

8. Which model printer is suitable for this solution ?

Recommended EP L1805, EPL1800.